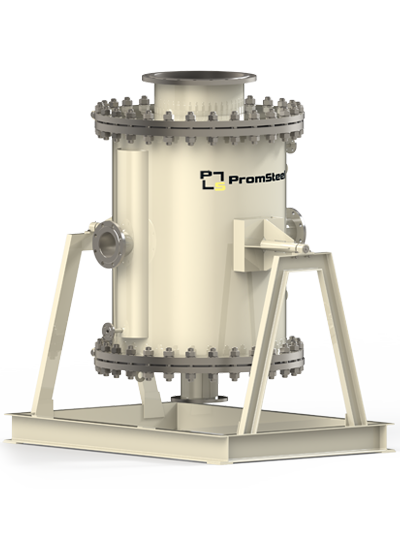

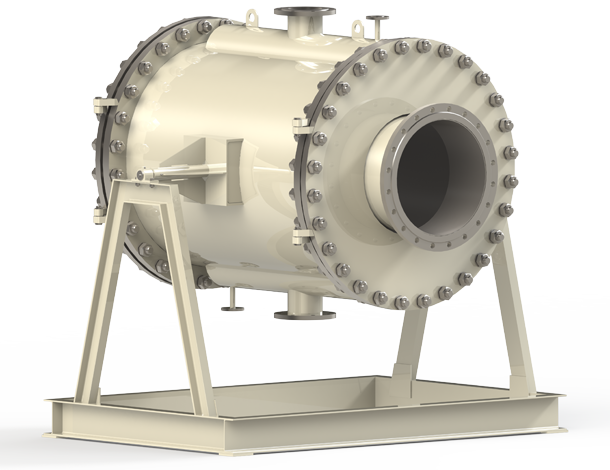

Spiral heat exchanger

Spiral heat exchangers in horizontal and vertical design are widely used for heat transfer processes between various liquids, vapors and gases in the oil, petrochemical, chemical, gas and other industries. This type of heat exchanger is successfully used to work with highly viscous and contaminated working media, as well as media with a high content of mechanical impurities.

Description and design

The heat exchanger consists of heat exchanger sheets twisted into a spiral and placed in a housing. The sheets are welded on one side to the central manifold, and on the other to the cylindrical body. The pins between the sheets help to form channels of constant cross-section. The body can be all-welded, or have removable covers for the possibility of mechanical cleaning of the heat exchanger channels.

- — Heat exchange spiral

- — Body

- — Fitting

- — Cover

Specifications

- Temperature range

- from -70 to +600 ° С

- Maximum working pressure

- 20 bar

- Heat load

- 50 MW

- Standard materials of the spiral

- stainless steels / SMO 254 / Titanium / Hastelloy С-276

Advantages of PromSteel's spiral heat exchangers

Ability to work on environments with a high content of mechanical impurities

Sustainable performance in contaminated work environments

Significant mileage between cleanings

Easy mechanical cleaning

Reliability and durability

Small hydraulic resistance

Significant intensity of heat transfer at increased speeds of heat transfer agents

Costs on both sides can vary significantly

Spiral heat exchangers are distinguished by their compactness, low hydraulic resistance and significant heat exchange rate at high speeds of heat carriers.

Do you have any questions?

Our experts will provide more information

Leave a request and we will contact you within 15 minutes.