U-tube heat exchanger

U-tube heat exchangers are distinguished by the presence of only one tube sheet, only one chamber for the flow supplied to the tube space, and a U-shaped tube bundle. The design of the tube bundle allows it to move freely inside the casing to compensate for thermal expansion. The design features of such devices allow them to be widely used for tasks with a large temperature difference between working media in oil, petrochemical, chemical, gas and other industries.

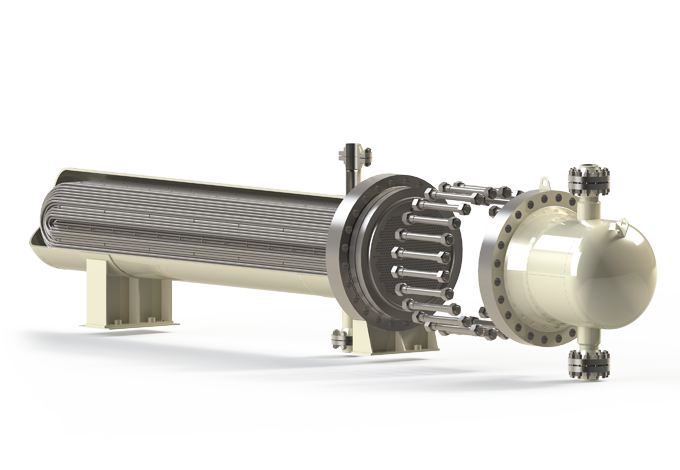

Description and design

The heat exchanger consists of a U-shaped bundle of heat exchange tubes fixed in one tube sheet, a casing, a chamber, a cover, fittings and supports. The design of the apparatus, testing and control of the manufacturing stages are carried out in accordance with the requirements and standards of PED, ASME, GOST or according to individual technical projects, taking into account the specific operating conditions and customer requirements.

- — housing

- — pipes

- — tube sheet

- — flanges

- — fixing bolts

- — fixing posts

- — cover

SPECIFICATIONS

- Temperature Range

- from -70 to +700 ° С

- Maximum working pressure

- 210 bar

- Heat load

- 200 MW

- Standard materials of pipes

- stainless steels / Titanium / copper / brass / carbon steels / alloy structural steels

Advantages of PromSteel's U-tube heat exchangers

RELIABILITY AND DURABILITY

INCREASED RESISTANCE TO WATER SHOCK

WORKS ON TASKS WITH HIGH VACUUM

WORKS ON TASKS WITH PARTIAL BOILING

WIDE RANGE OF TEMPERATURE AND PRESSURE

WORKS ON PROBLEMS WITH LOW MEDIUM DENSITY

DIFFERENT MATERIAL VERSION

ONE APPARATUS FOR ANY TASK

Since it is almost impossible to mechanically clean the inner coating of pipes in U-type products, the tube space of such heat exchangers must be kept in an environment where deposits do not form, which require mechanical cleaning.

Do you have any questions?

Our experts will provide more information

Leave a request and we will contact you within 15 minutes.