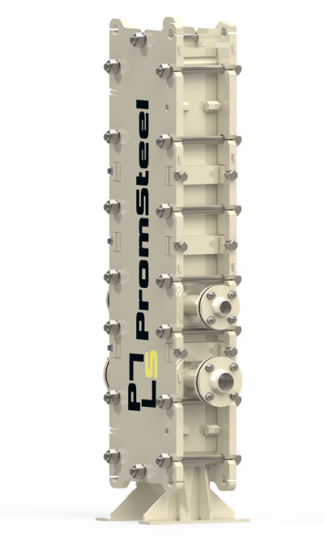

Welded evaporator

The welded evaporator is used in technological processes where it is necessary to transfer the heated medium from a liquid state to steam (gas). The welded evaporator does this job perfectly.

Description and construction

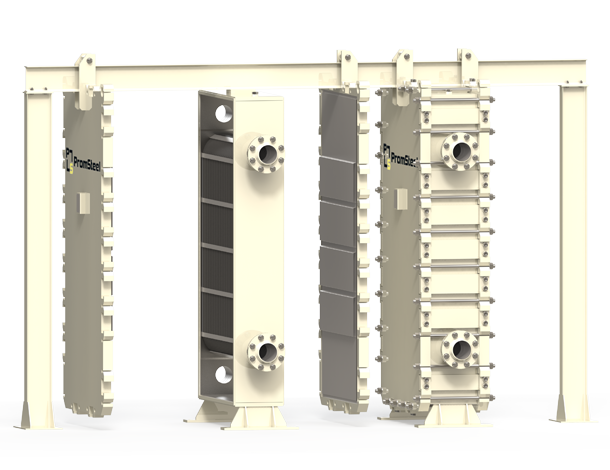

The heat exchanger consists of a welded body, inside which there is a welded package of heat transfer panels, and removable covers (plates). Removable (sliding) covers provide access to the internals of the heat exchanger for cleaning, maintenance and repair.

- — Housing

- — Pressure plates

- — Heat exchange package

- — Sealing gaskets

- — Tie rods and nuts

- — Flanges

Specifications

- Temperature Range

- from -200 to +650 ° С

- Maximum working pressure

- 100 bar

- Heat load

- 250 MW

- Materials

- AISI 304 / AISI 316 / Hastelloy С-276 / SMO 254 / Cronifer 1925 hMo / Titanium / Nickel 200

Advantages of the welded PromSteel's evaporator

Lack of

stagnant zones

Significantly extends the heat exchanger run between cleanings

Use in dirty

environments

The device works effectively in conditions of "dirty" environments and high-viscosity products

Compensation for thermal expansion

Provided in the design of the heat exchanger

Dimensions and weight

are several times less

Compared to shell and tube heat exchangers

Service by

1-2 employees

Without the use of lifting and transport mechanisms and special. funds

Differential

pressure

Can reach 70 bar between cavities

Revision, repair,

mechanical cleaning

Directly at the installation site without dismantling and disconnecting from pipelines

Location

of fittings

Possible options for the location of the fittings in the device for the existing piping

The welded evaporator is a heat exchanger with high economic efficiency due to its special design and ease of maintenance.

Do you have any questions?

Our experts will provide more information

Leave a request and we will contact you within 15 minutes.